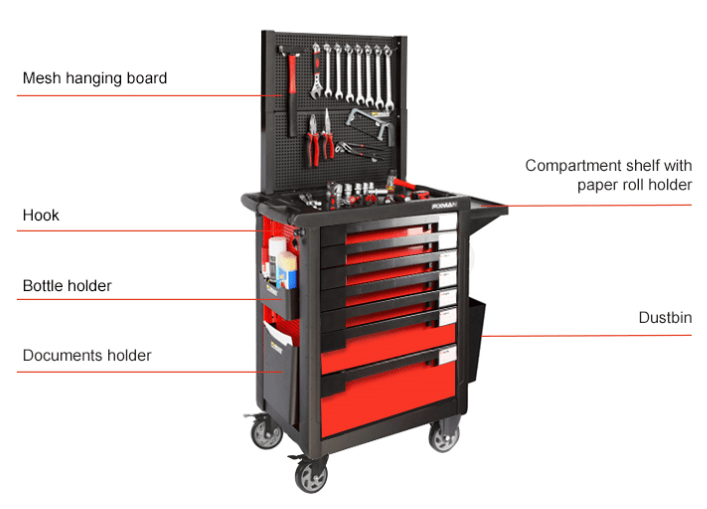

Roller cabinet is a mobile container device used to store hand tools. It is widely applied in automobile 4S shops, automobile repair shops, assembly lines of large factories, etc., such as bus factories, aircraft manufacturing enterprises, etc.

What are the types of roller cabinet?

1. Normal mobile tool cabinet: It is mainly distinguished from the drawer, from 1 drawer to 10 drawers, a total of 10 specifications, we call it F1RP1 to F1RP10, F1 is the code name of the series, R is the abbreviation of mobile (REMOVE), P It is the abbreviation of plastic (PLASTIC), and the number represents the number of drawers.

2. Heavy-duty mobile tool cabinet: It is also mainly distinguished from the drawer. We call it W1RM1 to W1RM10. W is the first letter of heavy in English, and M is the first letter of metal in English.

Generally, heavy-duty roller cabinets provide extended storage spaces as well as a higher loading weight.

8 things to pay attention when using roller cabinets

(1) Roller cabinet users can combine the recommended tool cabinet width (W), depth (D), and height (H) to form a proper size they want. It is also possible to configure a single-rail or double-rail drawer in the same roller cabinet to fully meet the needs of users.

(2) The drawer of the roller cabinet is equipped with a practical lock system, which will ensure the drawers not fall off when fully pulled out and will not slide out by itself. Therefore it is quite safe and reliable to use.

(3) The drawer of the roller cabinet comes with special guide rails, which can carry a large load. The single guide rail loads 100KG, and the opening rate is 92%, and the double guide rail drawer loads 200KG, and the opening rate is 100%. The bearing is used between the drawer and the guide rail and the push and pull are flexible and smooth.

(4) All drawers of the roller cabinet can be locked with a central lock, which is simple and convenient to use

(5) On the top of the cabinet, there are various accessories to choose: green striped rubber, border, drawing board, movable back board, square hole hanging board or louver hanging board to extend the function of the tool cabinet

(6) The bottom of the tool cabinet can be selected: flat pads, rectangular pads, angular pads, and adjustable pads, which are suitable for different placement needs of users

(7) After the tool cabinet is installed with casters, it becomes a mobile tool cabinet (roller cabinet)

(8) The horizontal and vertical plates in the drawer of the tool cabinet can be adjusted freely, and can be separated at will to store items of different sizes. Unitized parts boxes can also be selected for separation